Aldi RDC – Isle of Sheppey

CG Systems secured the pipework installation contract on the new Aldi Regional Distribution Centre (RDC) in June 2017. The new £50m RDC has created around 400 new jobs and measures more than 40,000 square foot. Have a look at the below pics for an idea of the scale of the project:

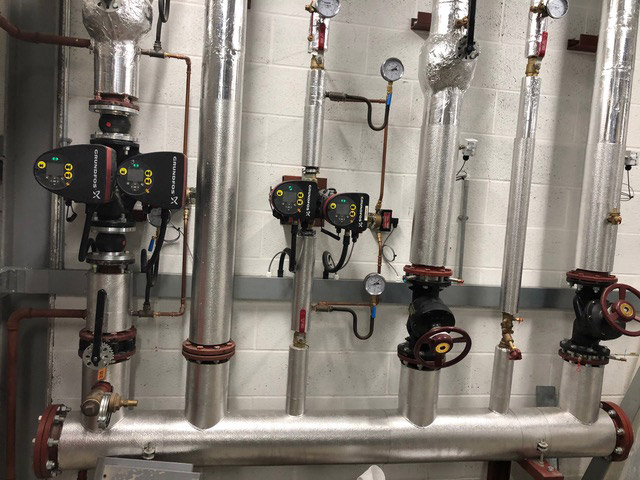

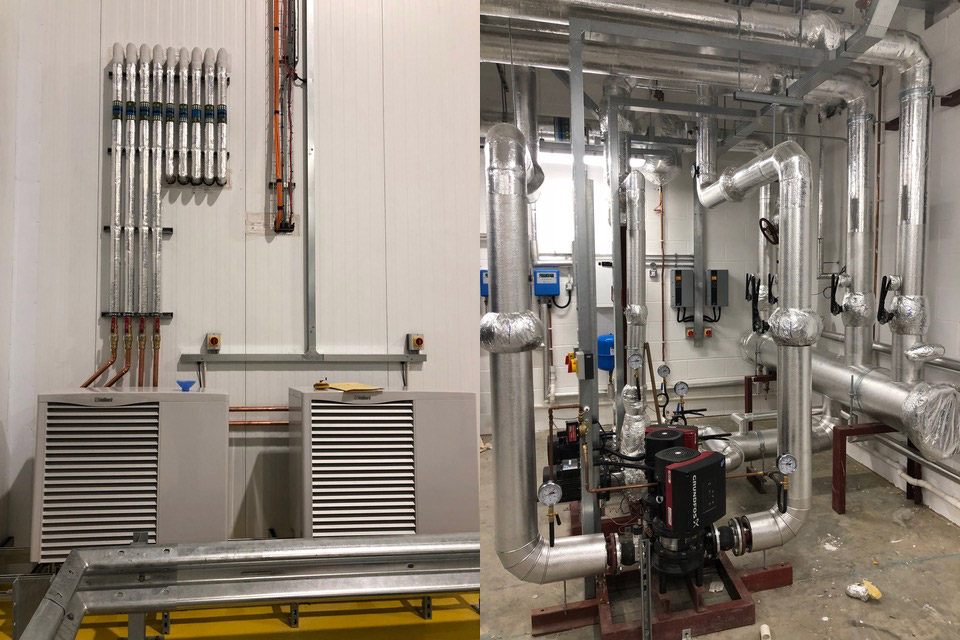

Our scope of work included:

- 136no Fan coil units on a 4 pipe system

- all the LTHW & CHW pipework on this system which was Geberit stainless steel mapress

- 3no Plant rooms incorporating the 2no Viessmann boilers

- 2no Beta Echos chillers and 2no Barkell air handling units

- Over 500meters of welded gas pipe serving 9no Reznor warm air unit heaters

- 2no Vaillant air source heat pumps

- 1no GRP water tank and pumps.

All of the Domestic water services pipework was installed in Geberit Copper Mapress with all the valves on the project manufactured by Crane.

Once again we received fantastic support from our suppliers and the engineers involved in the project proved why they are an invaluable part of our team.

We recently achieved Prime Cost (PC) on this project, which makes it the longest running and largest project we have carried out to date.

If you’d like further information on our involvement in this project, feel free to contact the CG Systems team on info@cgsystems.cc.