Gas Line Installation – Global Online Retailer

Christmas is around the corner and as one might imagine, retailers are operating in sales overdrive; so when we were commissioned to install a gas line to an existing Lennox Air Handling Unit (AHU) for a global online retailer, the team at CG Systems was prepared to work out of hours so as not to disrupt operations (never a problem for us!).

The work comprised the installation of 80 meters of 76mm Geberit Stainless Gas pipework and fittings, which took place at an ‘above level’ working height that required the operation of scissor lifts to give us access to the gas line. We opted to use the Novopress ACO203XL pressing tool as this meant we did not have any trailing power leads (created by the height at which we were working) and this managed to avoid any potential Health & Safety safety issues.

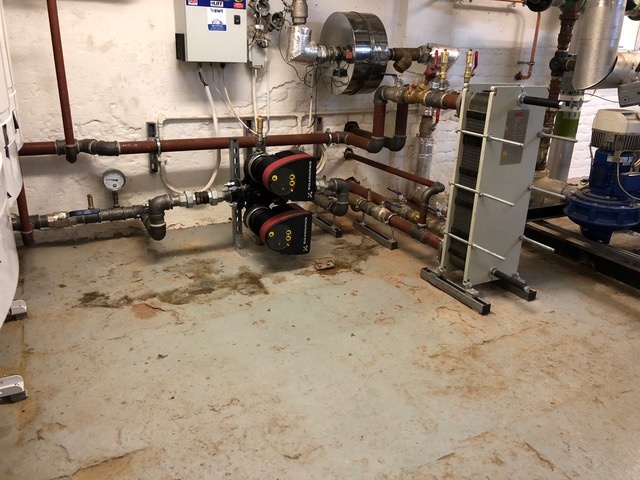

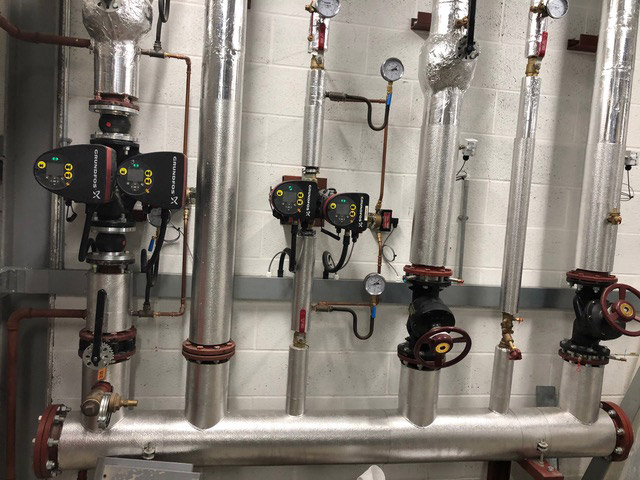

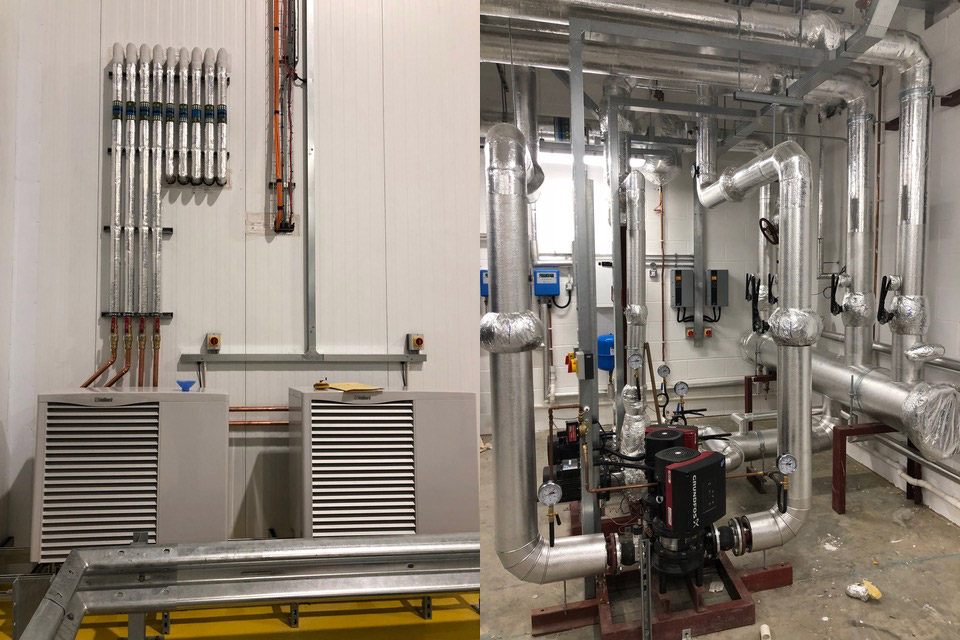

See below for images of the installation in process:

If you’d like further information on our involvement in this project, feel free to contact the CG Systems team on info@cgsystems.cc.