The ‘Ruislip project’ is a great example of the lateral thinking that is often required in the type of contract work that the team at CG Systems is recruited to do. In this instance, an existing building on the site in question was to be demolished and all the service pipework for 3 Sanyo Gas Fired Heat Pumps was fixed to this building. Our team was contracted to run three new refrigerant circuits as well as a new natural gas line to feed each unit. Have a look:

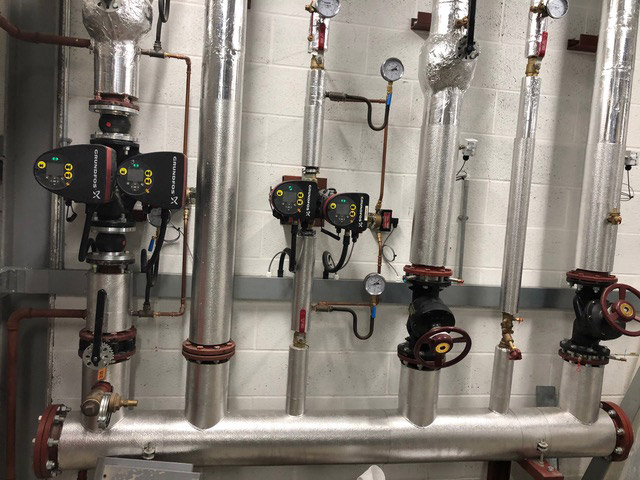

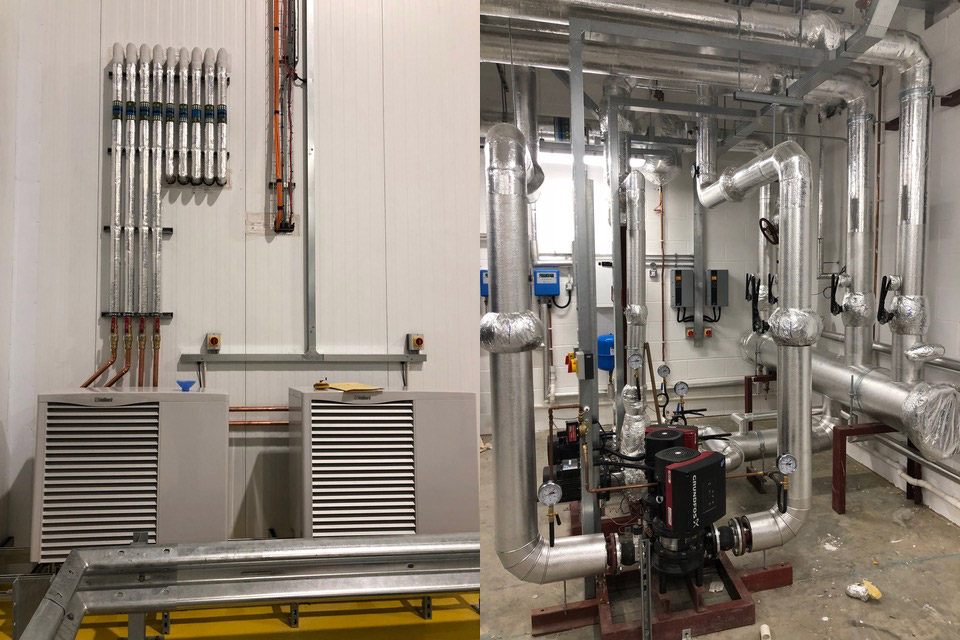

The team carried out some very tidy welding on the 4-inch branch that we tied in to the existing 6-inch gas line with the remainder of the natural gas pipework being run in Geberit stainless steel pipework and fittings. The final connection was carried out by hot-tapping the service as this ensured the least amount of down time possible, which was critical on this project due to £27m’s worth of stock in the warehouse (and all the product temperature critical).

The Air Handling Unit served by the GHPs is housed on the first floor of the warehouse, which made running the refrigerant pipework an interesting challenge, but nothing that our capable team couldn’t figure out.

These GHPs are fantastic units as they give customers the option to introduce additional cooling capacity into a property where the electrical capacity has already been utilised for other applications.

If you’d like further information on our involvement in this project, feel free to contact the CG Systems team on info@cgsystems.cc.